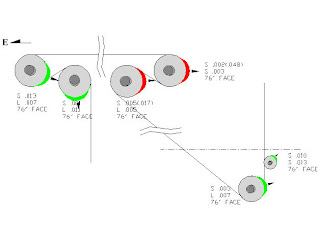

A steel mill galvanizing line in the mid west was experiencing severe bearing wear of the pot equipment in the zinc tank. Projected bearing life was 6 weeks, but the mill was stopping production every 2 weeks to replace badly worn bearings and was running very close to complete bearing failure on several occasions.

After attempts to align the pot equipment by a local company using a Laser Tracker failed, AIM was brought in to do a survey of the galvanizing line pot equipment. A one day AIM survey, and corrections based on the survey that day, produced an immediate and dramatic change to the process. Bearing life improved to 8 weeks and strip tracking throughout the pot and tower areas improved as well.

Score: AIM = 1, Laser Tracker = 0

After attempts to align the pot equipment by a local company using a Laser Tracker failed, AIM was brought in to do a survey of the galvanizing line pot equipment. A one day AIM survey, and corrections based on the survey that day, produced an immediate and dramatic change to the process. Bearing life improved to 8 weeks and strip tracking throughout the pot and tower areas improved as well.

Score: AIM = 1, Laser Tracker = 0